Masking tape is a type of adhesive tape that temporarily conceals surfaces where finishing work is not intended. Soldering, blasting, spraying, coating, plating, and polishing are temporarily protected by masking tapes while these processes are performed on surrounding surfaces. The tape contains a pressure-sensitive adhesive that can be easily torn and dispensed. The adhesive used in the making of a masking tape is the key element since it leaves no residue, which makes the tape extremely useful for carrying out many tasks. Read More…

Carolina Tape & Supply Co. is a distributor & custom tapes converter offering 100% satisfaction. As one of the leading tape suppliers in the nation, Carolina offers an array of quality products & services to your company.

CS Hyde is a leading distributor and converter that supplies a wide variety of high performance tapes with pressure sensitive adhesive. Our tape is available in materials such as Teflon™ Fluoroplastic, Kapton®, UHMW, Silicone, and many more. Since our fouding in 1996, our team at CS Hyde has continued to be committed to our customers and building long-term relationships by providing top...

CFS is an ISO 9001:2015, 3M™ Preferred Converter with a large inventory of industrial masking tape products, including high temperature polyester tapes, polyimide tape, and crepe tapes. Our tapes can be used for powder coating, e-coating, anodizing, and many other applications. As a 3M™ Preferred Converter, we can custom slit or die-cut most of our tapes to your desired specifications. CFS...

As a tape supplier our products serve many diverse industries such as aerospace, artistry, graphic arts, food and drink as well as many others! For over forty years we have been providing the highest quality tape products with the widest selection. Just a few examples of the products we offer are 3M masking, Teflon, gaffers tape as well as many others. To learn more about what we may be able to...

Budnick Converting is a family-owned custom converter and distributor of adhesive tapes, foams, and other flexible materials. We have over 70 years of experience in the tape and converting industry and offer adhesive tapes, foams, films, foils, and other specialty materials from every major manufacturer. Our primary converting services include slitting, die-cutting, printing, spooling,...

At Magnum Tapes & Films, our dedication to excellence in tape solutions is the cornerstone of our commitment to providing superior products and services to our valued clientele. With years of experience and a deep understanding of the tape industry, we have established ourselves as a trusted leader in delivering high-quality, customizable tape solutions. Our product line features a diverse range...

More Masking Tape Manufacturers

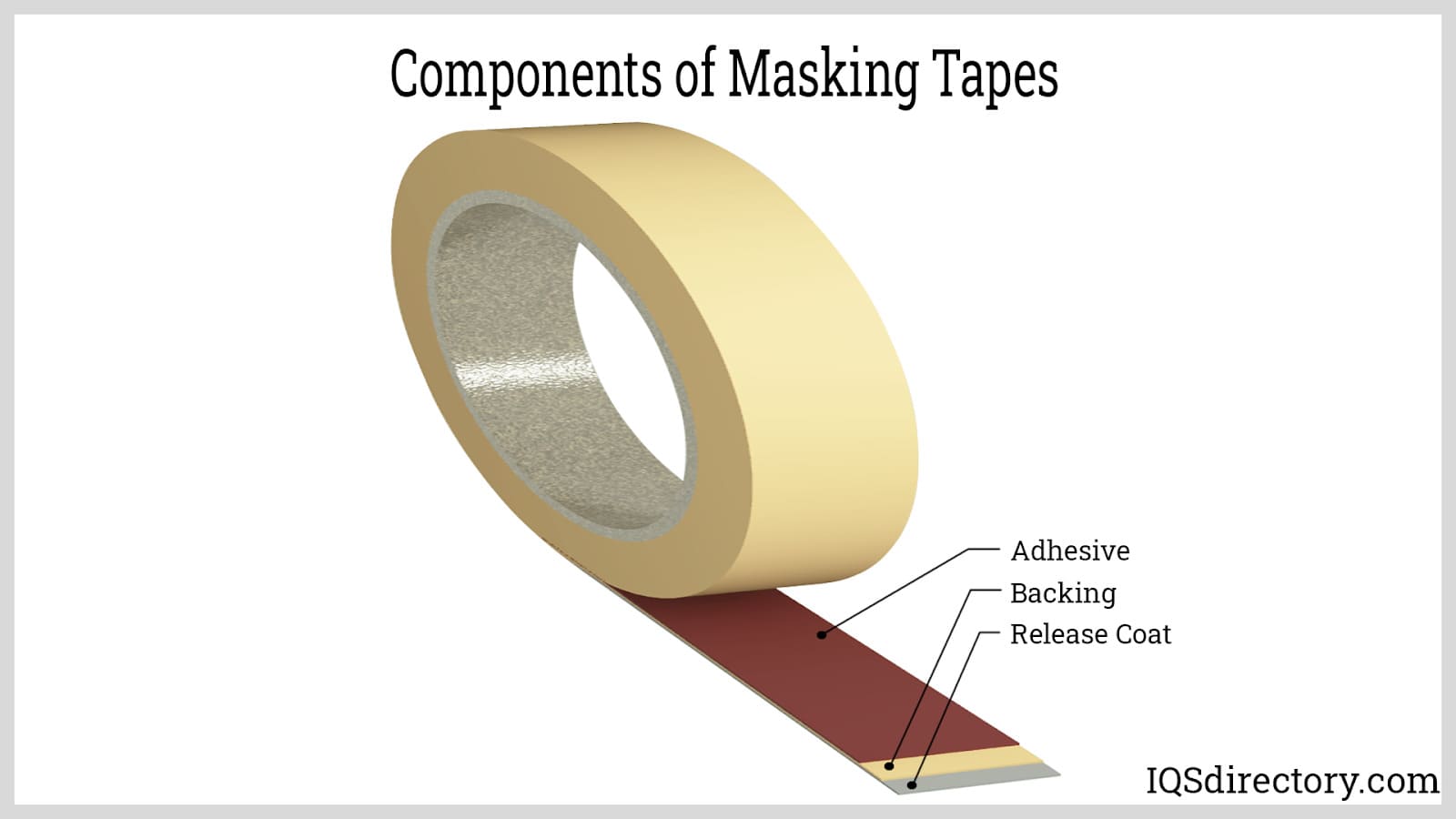

Components of Masking Tapes

A masking tape consists of two layers:

- The backing is a thin, moist crepe paper that can be shredded by hand.

- The adhesive layer can be solvent-free, hot melt, or acrylic-based, depending on the amount of adhesion required.

Materials Used for Masking Tapes

The backing for the masking tape can be done with several types of material:

- Paper: Paper backings are one of the most common; they are inexpensive and often made of kraft or crepe paper.

- Polyester: These polyester material carriers have a high resistance to solvents and have ideal aging and clarity characteristics.

- Glass: These are enforced with glass or fiberglass particles which drastically increase heat resistance up to 302 °F (150 °C).

- Foil: Backed by aluminum, aluminum-reinforced material, or lead, metal foil tapes offer high reflectivity and resistance to heat.

- Ceramic: Consisting of a mix of ABS fibers or some other ceramic textiles, this type of backing is appropriate for extreme heat conditions.

- Foam: In this backing, an adhesive is covered by a liner in the form of a tape, film, or laminate in adhesive-coated polyolefin foams.

Due to the temporary tape's intent, the chosen adhesive must be carefully assessed depending upon the task. It should be residue-free, which limits the options.

There are four bases for adhesive:

- None: These are non-adhesive tapes with no pre-applied adhesive on the masking tape roll. These are self-adhering and highly rely on the coefficient of friction to remain sticky.

- Rubber: The material consists of an adhesive with highly flexible compounds based on butyl, nitrile, and others.

- Acrylic: These are made of an acrylic substance that, once applied, accomplishes its job to the best of its ability by adhering and having strong shear and peel strength. These are easy to prepare and have a good amount of resilience.

- Silicone: Consisting of silicone material, some silicone adhesives, while accessible as a pressure-sensitive application, may require air or UV or EB radiation to cure. Rather famous for their resistance to extreme temperatures as high as 608 °F (320 °C), they are quite flexible.

Types of Masking Tape

Plating Tape:

Red Plating tape consists of a polyester backing and a silicone adhesive used on circuit boards during the tin/lead stripping and gold plating process.It may also be used to paint and varnish silicone paper films.Plating tapes can withstand acids, chemicals, and extreme temperatures.

Painter’s Tape:

Painter's tape is explicitly made to hide vehicle components that don't need to be painted.Masking tape ensures clean and crisp edges and prevents the paint from spilling, which is why it's now used for all types of professional and DIY painting.

High-Temperature Resistance Tapes:

High-temperature resistance tape consists of polyester film tape with a high-temperature-resistant adhesive. This tape is used in various electrical/electronic device production processes due to its intense heat resistance and electrical insulation.

Vinyl Tape:

Vinyl tape is also frequently known as insulating tape. Vinyl tapes are a type of pressure-sensitive tape used to insulate electrical cables and other conductors of electricity.

Masking Tape Specifications

There are two major geometrical factors to consider when it comes to tapes: width and thickness.

Masking Tape Size (Width)

The width of the tape is measured across predefined edges. For example, a narrow-width tape might be used for masking corners or tight spaces, whereas a wider tape might be required to cover large areas.

Masking Tape Thickness

The distance between the tape's two flattened surfaces (carrier and adhesive) is measured in thickness. It is typically measured under pressure using a gauge and represented in mills or thousandths of an inch.

Masking Tape Applications

Masking tapes are widely used in high processes, including thermal spraying, shot anodizing, and electroplating. These tapes are available in many designs to suit their specific needs. Moreover, they are most commonly used to contrast colors and components during painting.

A few more masking-specific applications are listed below:

- Masking for Chemical Conversion: For chemical treatment (immersion) without leaving any residue.

- Masking for Metal Coating: Enduring solutions for all, even the most restrictive treatment types.

- Masking for Varnishes: A solution adaptive to all paints and varnishes.

- Masking for Mechanical Treatments: Durable and strong film solutions ideal for blasting and sandblasting operations.

Benefits of Masking Tapes

The following are benefits of masking tape:

- Has excellent consistency and strong adhesion.

- Acts as a moisture seal/environmental barrier in industrial work.

- Replaces bolts, rivets, welds, and other mechanical fasteners by providing structural strength.

- Provides strong adhesive, good conformability, medium or high viscosity, and tape for various temperature stages.

Choosing the Right Masking Tape Supplier

To make sure you have the most beneficial outcome when purchasing masking tape from a masking tape supplier, it is important to compare at least 5 companies using our list of masking tape suppliers. Each masking tape supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each masking tape business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple masking tape companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services